Ok, Back to the business of building a tyre and strawbale hybrid.

Remember; when a home dreams green it dreams strawbale.

© gvroom

Micheal Renalds books Earthship’s 1&2 Had a huge influence on me and in my opinion a must read for anyone interested in sustainability, green and natural building etc… His concepts are sound and harmonize well with the permaculture ethos.

Personally I chose to build a hybrid using Earthship concepts below grade and strawbale above grade. I chose this option for a couple of reasons. One, packing tyres is a hell of a lot of work, and one only needs so much mass for an efficient passive solar home.

I have since built 3 homes using tyres to get above grade. They work great when berming into the earth and honestly are not that bad to pack from the ground to about chest high. After that they get incrementally more labor intensive.

|

| It is important that you keep your courses on the same level! |

I think tyres make excellent Foundations and stem walls. Unlike concrete which is brittle and therefore inflexible, tyres can move with the earth but because of their width still remain stable. And we all know that the ground is in a constant state of flux.

When collecting tyres it is important to get all the same size. In my case they were R-75-15. You will want to learn what the most common SUV or truck tire is in your area, as they will be the easiest to collect. My county is rural with about 14000 souls and supports 3 tire stores. With that said I was able to collect 300 tires in about 3 weeks. Keep in mind these were all the same size tires. That puts into perspective how many tires we use and exemplifies the importance of finding ways to use this soon to become precious resource, and they make great foundations.

When prepping the ground to use Tyres or REU’s [ rammed earth units ] the same rules apply as to any other footer/foundation. The grade needs to be level and on “undisturbed soil” or packed to 50 psi per engineering specs.

This is usually done with moistening the dirt and tamping with a mechanical tamping device.

My approach to packing tires is to use two people working as a team with one person on opposite sides of the wall. One person shovels and packs while the other pry’s open the rim of the REU with a pick axe. The shoveler first fills the tire and then packs out the inside of the tyre first by hand and then with a small 2 pound sledge hammer. This will fill the tire to nearly the required amount with the least amount of effort.

Note: when the REU [R-75-15] is packed to 10” you have achieved the proper psi per engineering specs of 50 psi. [I have the specs on this and would be happy to share them]. It is also important that you keep each course on the same level. Sooo---always shoot grade and use string lines. We will be discussing more on this as we go.

|

| jumping Jack Tyre, it's a gas, gas, gas! |

Using between 3 & 400 tyres in a project would take a crew of 6 people about a week to complete. The cost compared to what the same amount of mass in concrete would cost me with labor included.

One reason why REU’s work so well is that the rubber acts both as an insulator but also as a conductor. So as one tyre heats and becomes warmer than the tyres around it the rubber helps to conduct the heat to the surrounding cooler tyre.

|

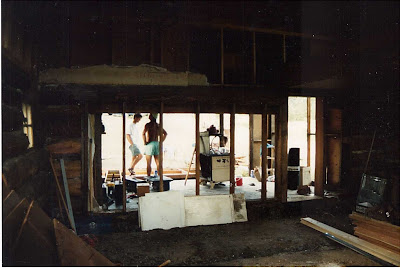

| this is about 500 sq. ft. and took a work party of friends a long weekend to accomplish what you see here.Oh! and a lot of beer. |

Here we are on our last course of REU’s. In the background you see a packing team giving their last touch to a tire. Note the small sledge. In the foreground you see rebar poking out of the tires. The rebar is beat vertically down through the tires to tie them all together. To accomplish this I used the same tool that is used for t-posts in fencing. The rebar is then left long to tie into the concrete bond beam.

In this photo we see-----Jubilation!, and for good reason. We are celebrating the successful pour of the bond beam. Now this was no easy feat. First of all our forms left allot to be desired. The beam was formed on top of the tires, as wide as the tires, about 30”, and a foot thick [total overkill I might add], keep in mind that we are at the Way Back Inn and getting a cement truck up there, well that alone is asking a lot, not to mention that on that day I had a crew of two. Anyway, about the bond beam, the purpose of the bond beam is exactly as it is described; to bond the tires together and to create a level surface from which to build off of. Note the rebar sticking out of the bond beam. Those were for stabbing into the first course of straw to tie everything together. This I would later learn is not necessary and would not do this again on my next 7 homes.

Now one of the laws of thermal dynamics state that when two materials of different temperatures are touching, heat will got to cold and vice versa. So in the case of using mass as a heat sink for your home, unless you don’t mind the earth and or elements drawing the heat stored in your mass down to its temperature, you have to isolate/insolate your mass from these elements. If you do then the mass will maintain a consistent temperature based on the ambient temperature of your home. I highly recommend doing this. It is also important to create a moisture barrier between the earth and your tyre wall/footer/foundation. Condensation will eventually deteriorate the integrity of your wall and will also act as a heat syphon.